Weighteknic Solution

Measure Accurately and Save Earth

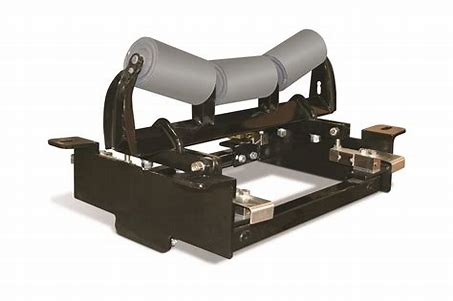

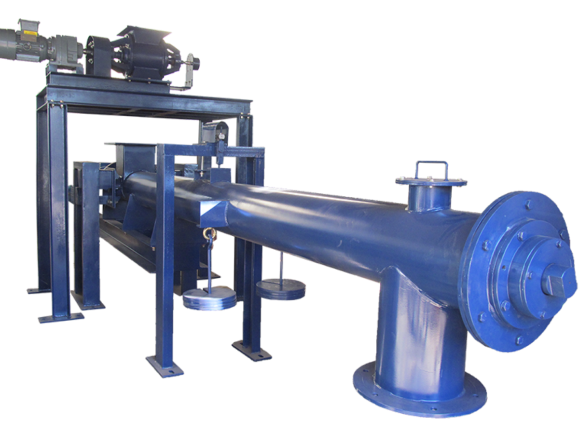

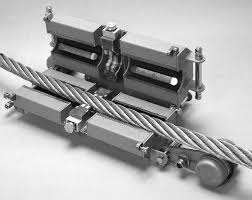

Weighteknic Solution, founded in 2024 by a team of highly professional, dedicated and enthusiastic engineers, is a high scale manufacturer of weighing, feeding and transportation machineries handling all kinds of bulk materials. The production range includes belt weigh scales, belt weigh feeders, loss-in-weight-feeders, solid flow feeders, weighing screw feeders, batch scale, cranes scales and all types of static weighing system. Company involves in design, engineering, manufacturing, supply and commissioning of industrial process measuring and control Equipments, safety Equipments, solar items and automation products. Company is a multifunctional organization engaged in engineering solutions and services for industrial and infrastructure segments. We provide all types of weighing systems (Dynamic and Static) in steel, cement, mining, chemical, plastic, power and transport industries.